Timing Belts

with cleats

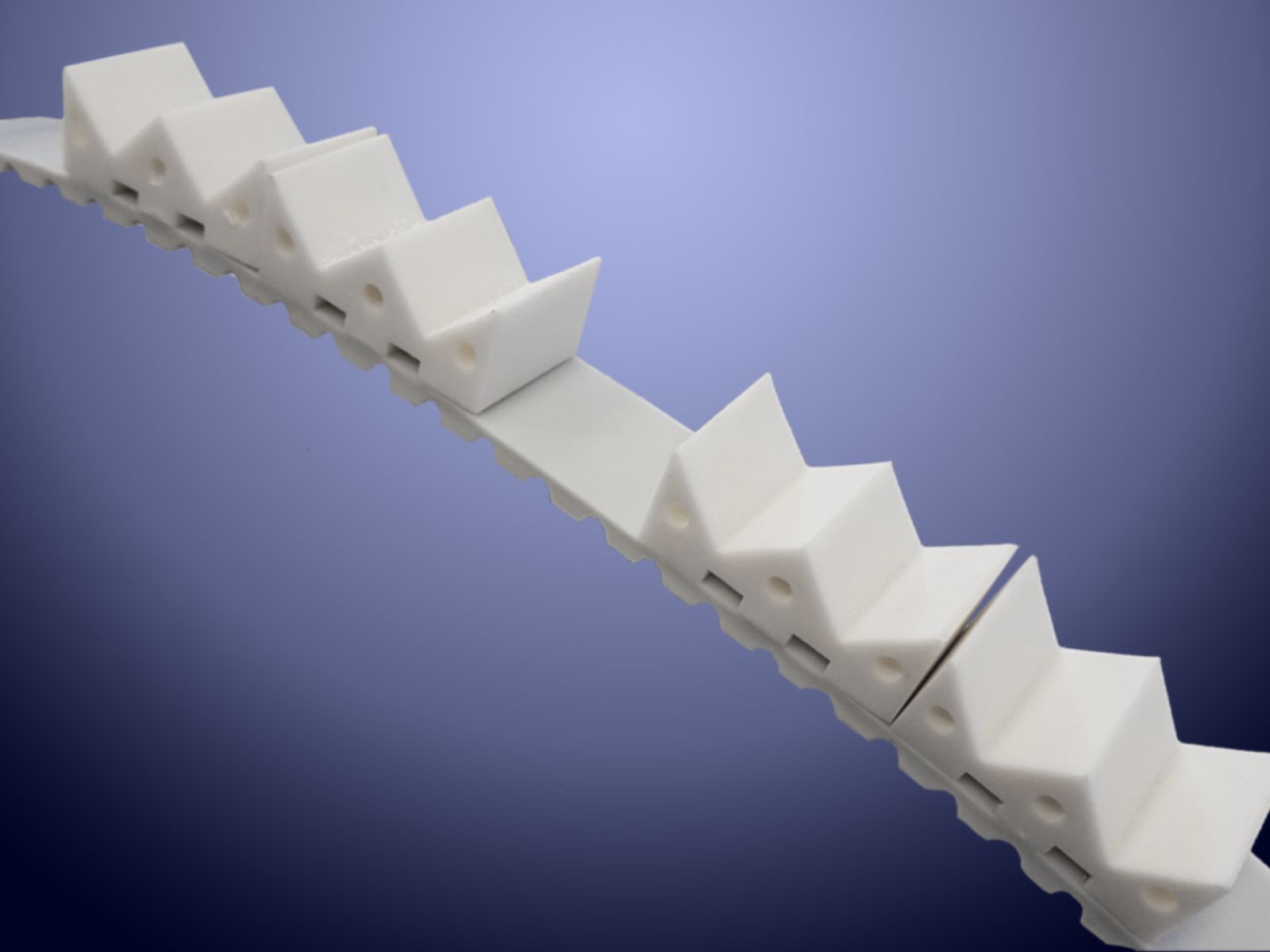

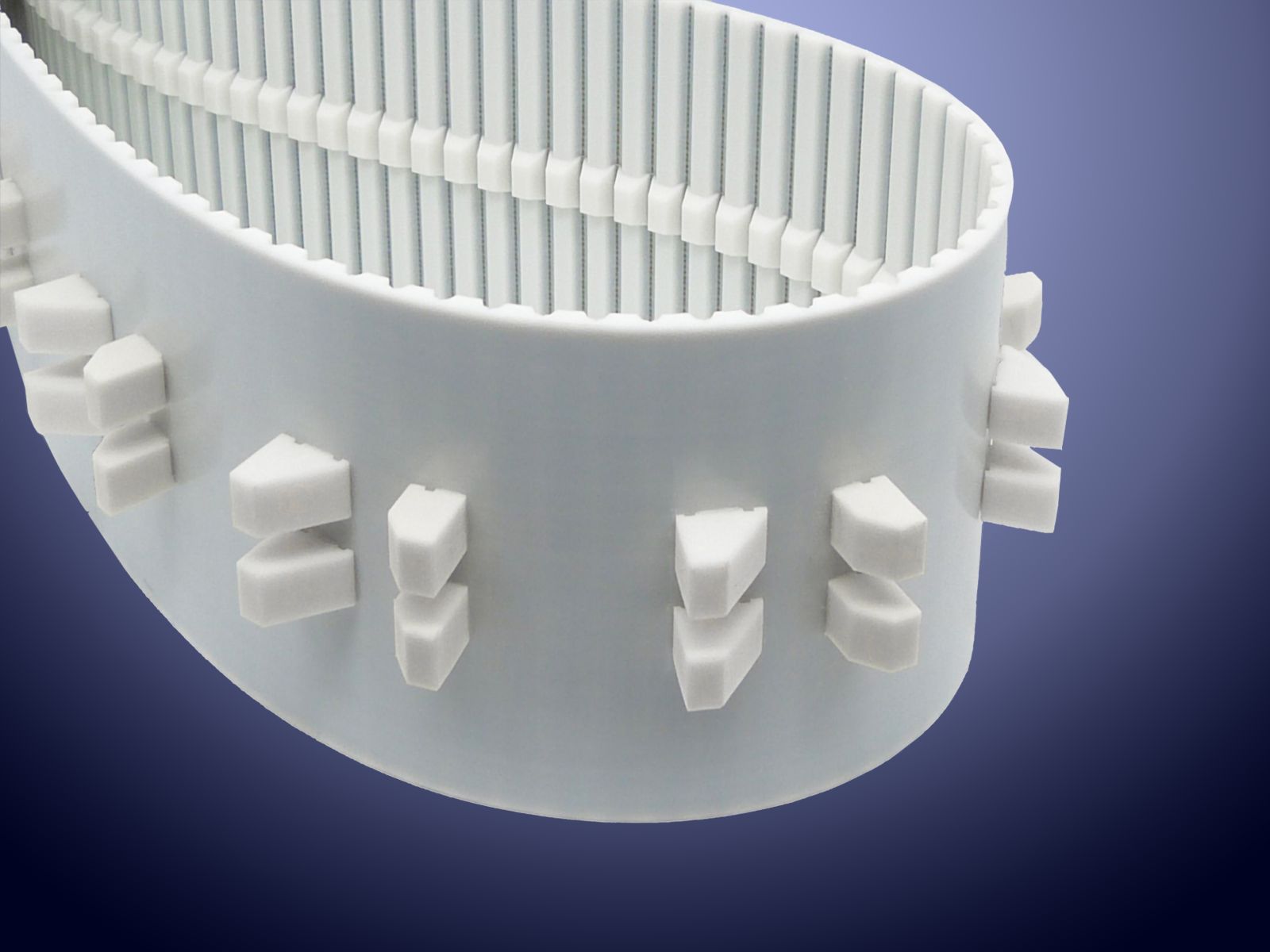

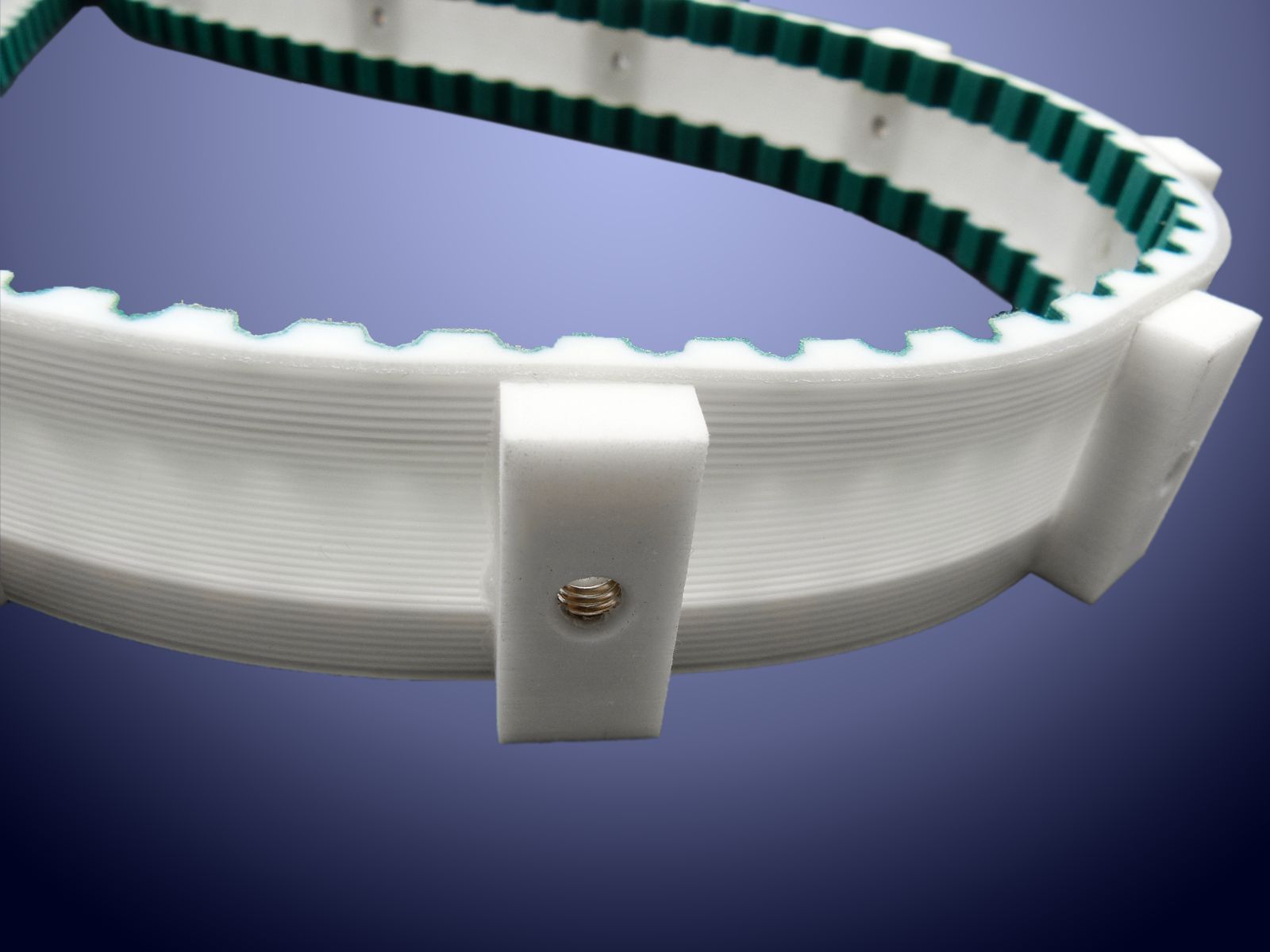

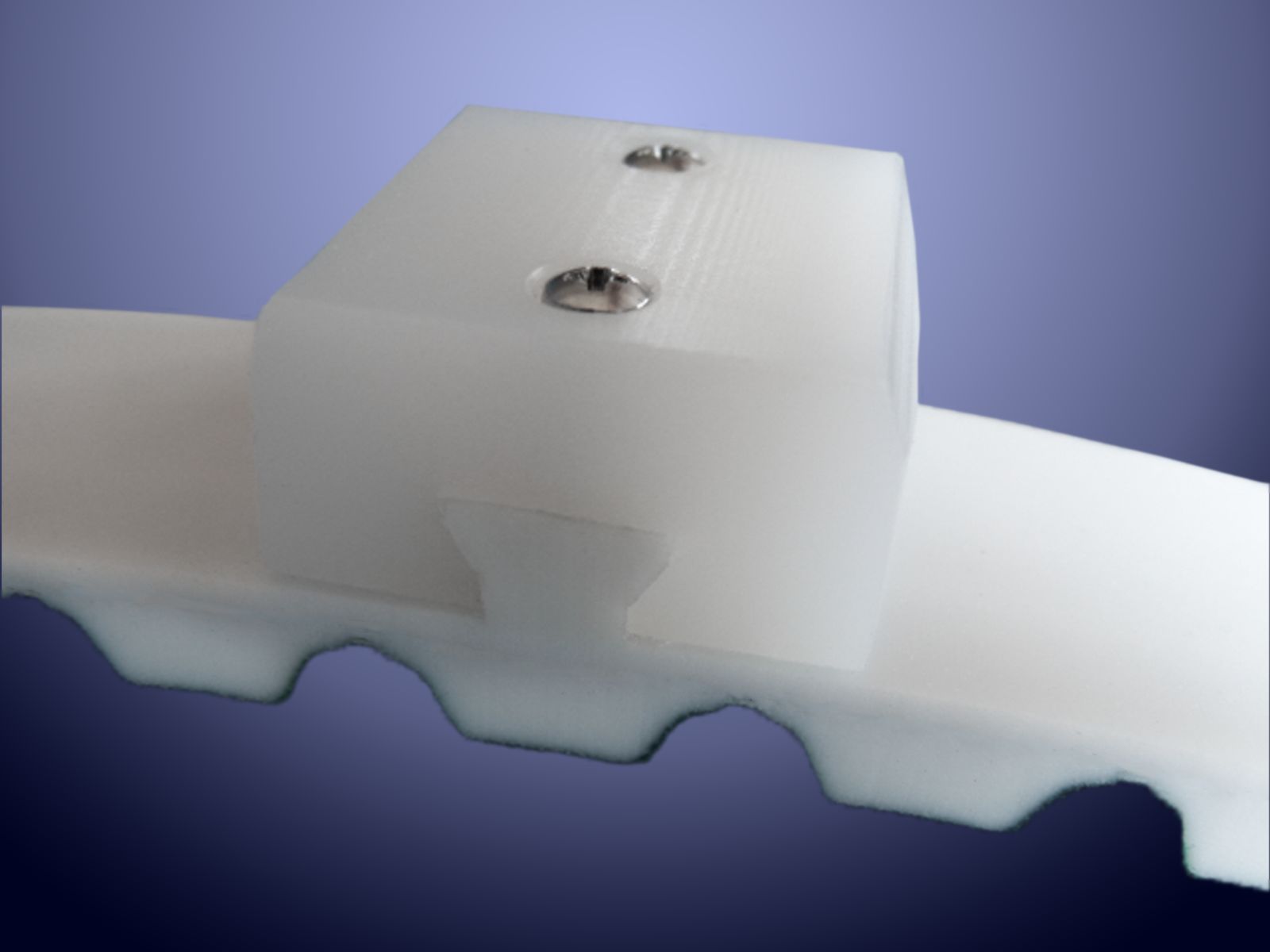

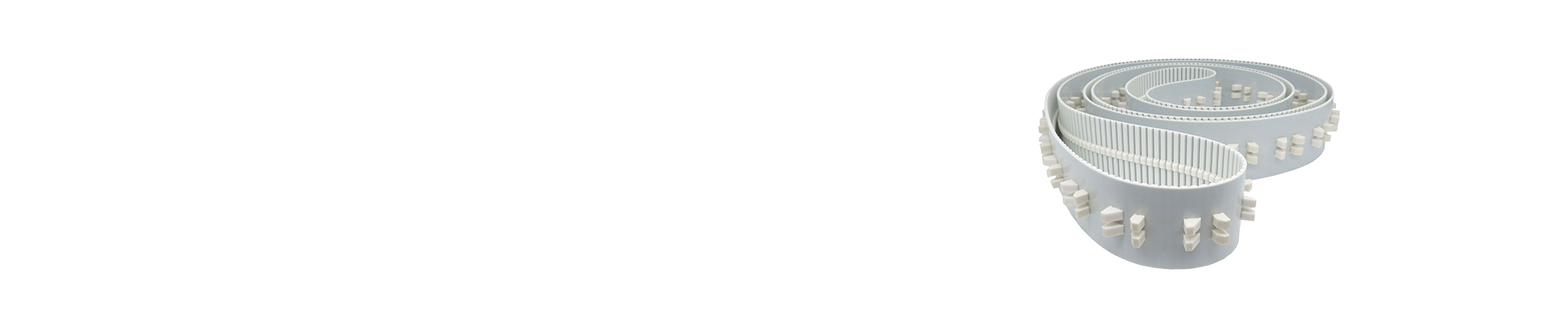

The thermoplastic polyurethane (TPU) attachments are applied to the timing belt and can be welded on the back in any position, allowing the customer to choose the attachment spacing position (unlike for belts with false teeth it does not have to be a multiple of the tooth pitch used).

Usually the geometries to be created are made through mechanical machining, but in cases where the quantity of attachments is very high we can produce a mould in order to optimise the manufacturing costs

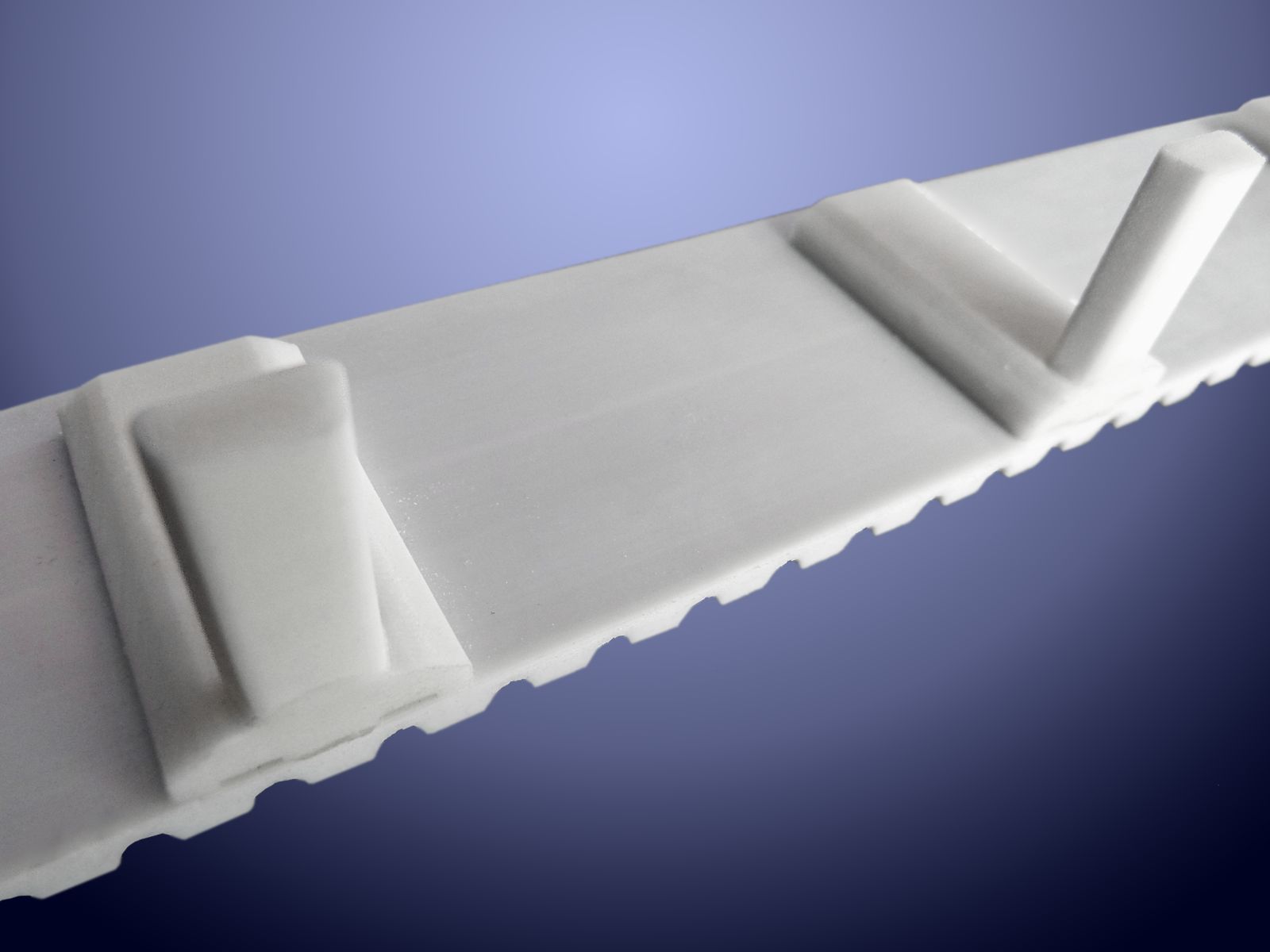

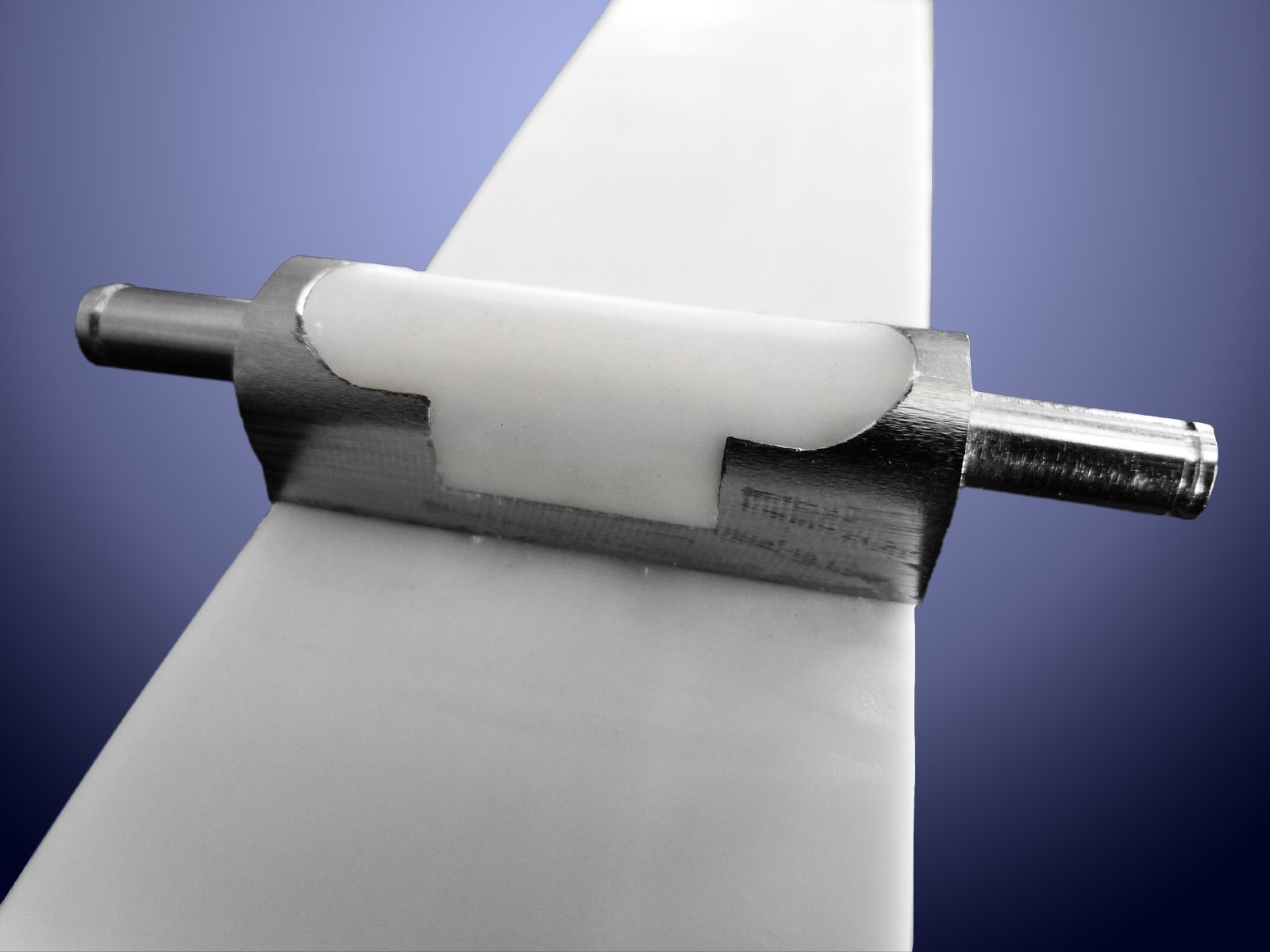

This production process also offers the significant advantage that metal parts can be inserted within the polyurethane in order to reduce the consumption in the area in contact with the transported product or, where required, be used to anchor other components (magnets, threaded rods, inserts with threaded holes …)

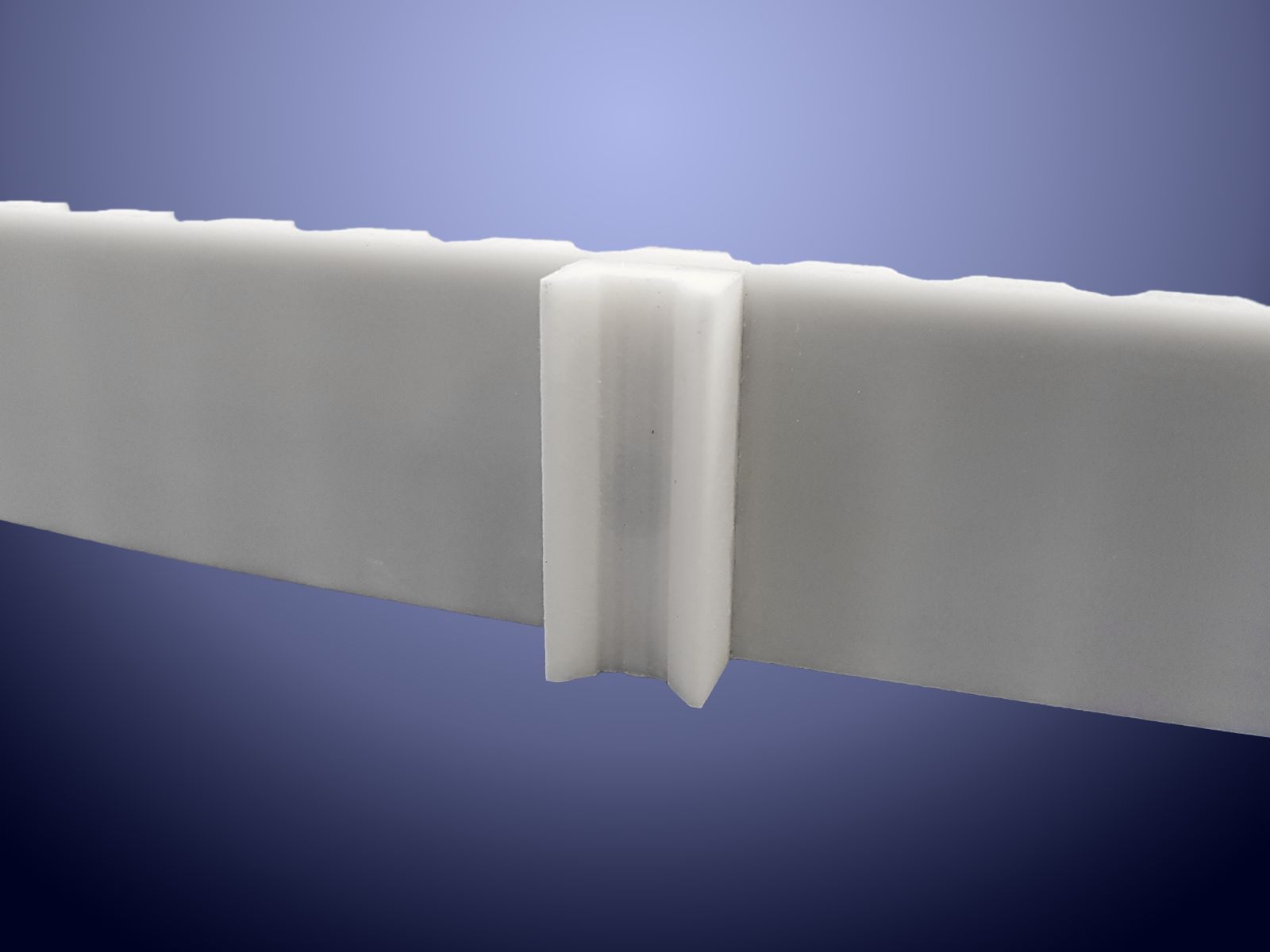

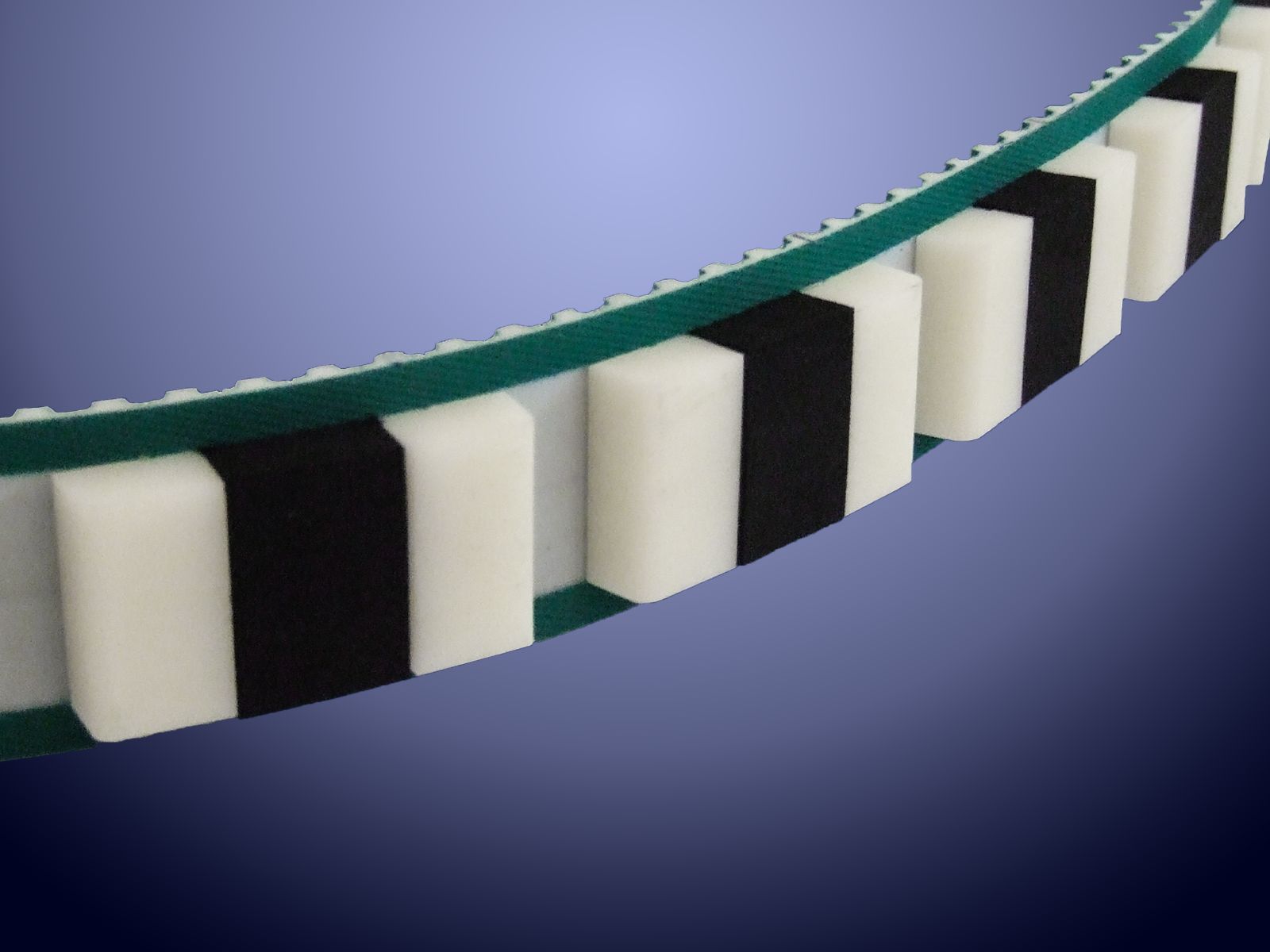

Timing belts used in conveyors are often subjected to high levels of acceleration, and the specific weight of the polyurethane often does not allow the required geometry to be created because the result would be an excessively heavy attachment. By welding a dovetail attachment to the back of the belt, it is possible to make an interference fit of another attachment in a lighter material (e.g. glass-fibre reinforced plastic, carbon-fibre …).

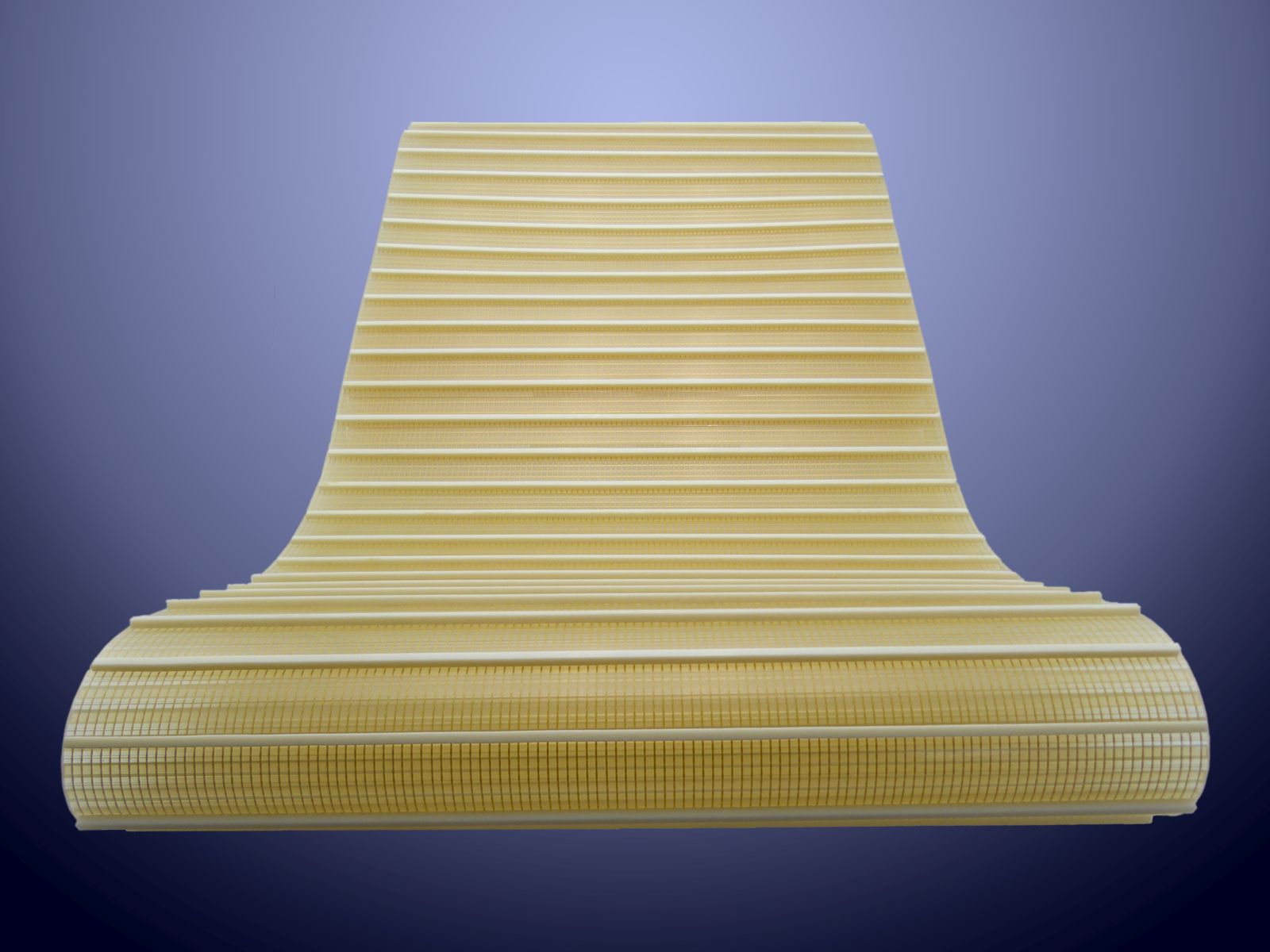

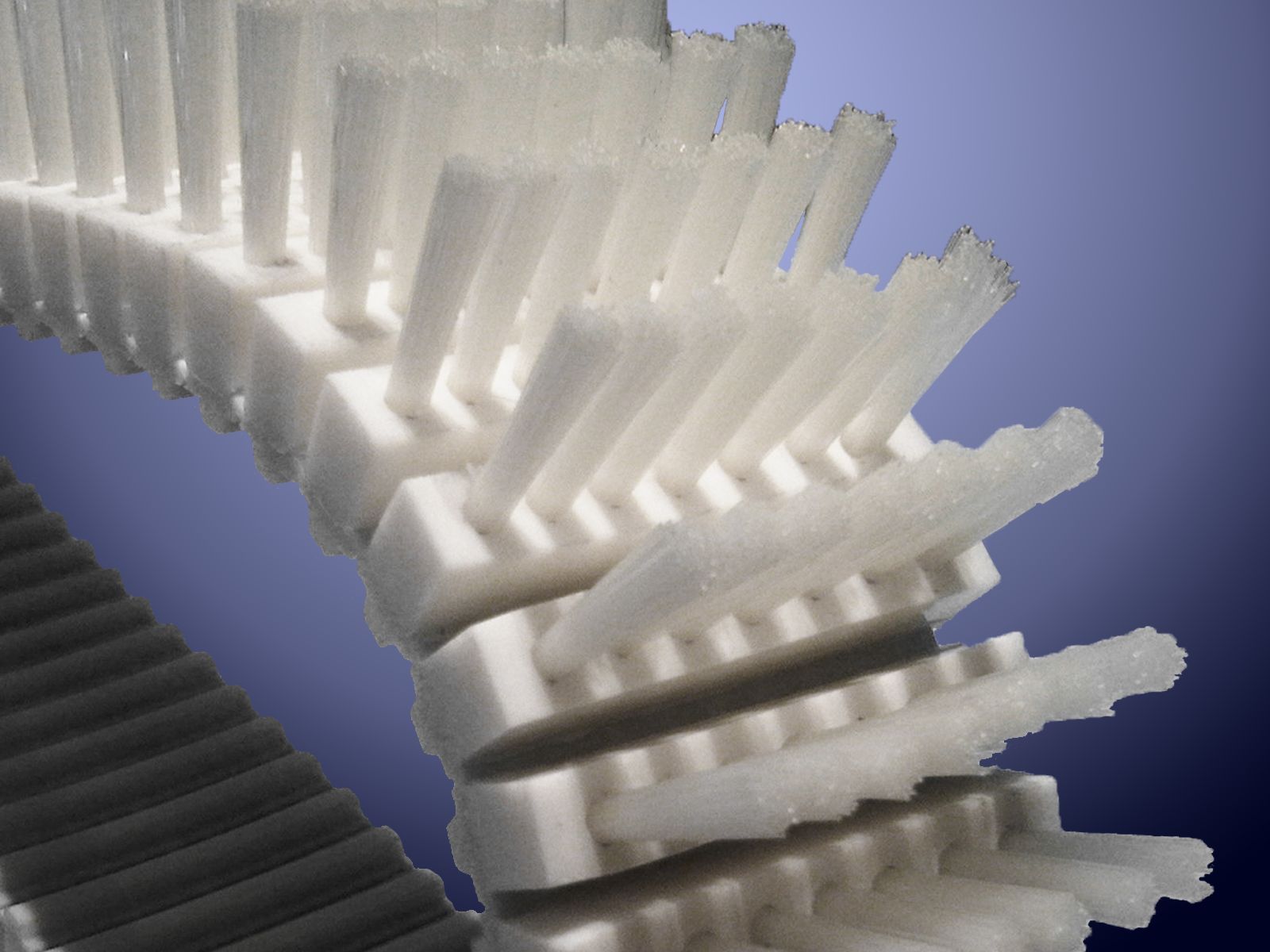

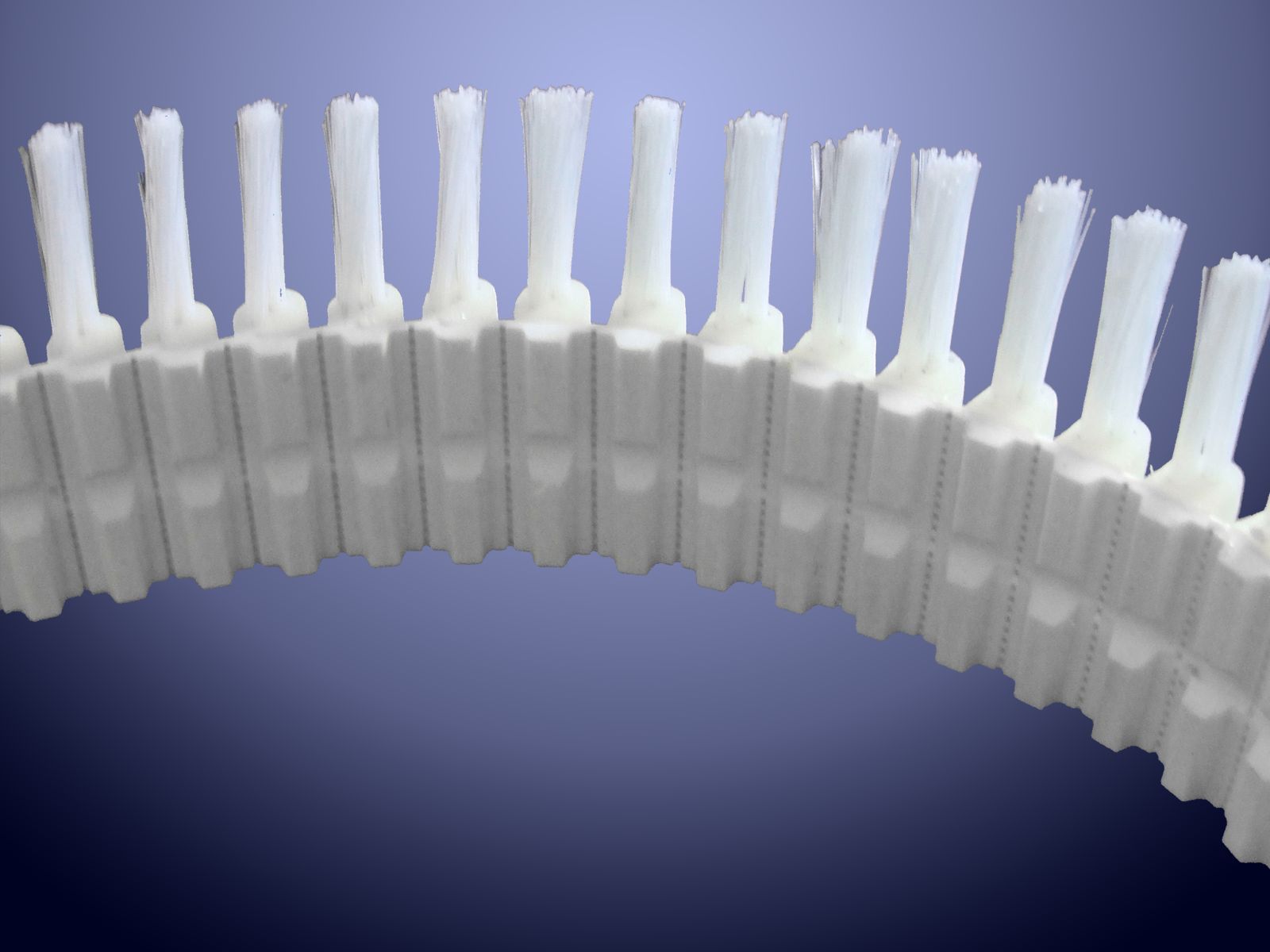

When transporting fragile objects it is not possible to use rigid attachments because this would run the risk of damaging the integrity of the product. By producing perforated attachments it is possible to insert brushes in order to create a soft back to the belt where the objects can fall and be transported with no risk.