Franke Bearings

Bearing elements are Franke’s product par excellence; the simplicity and versatility of this solution allow customers to achieve results which would be difficult with competitor products.

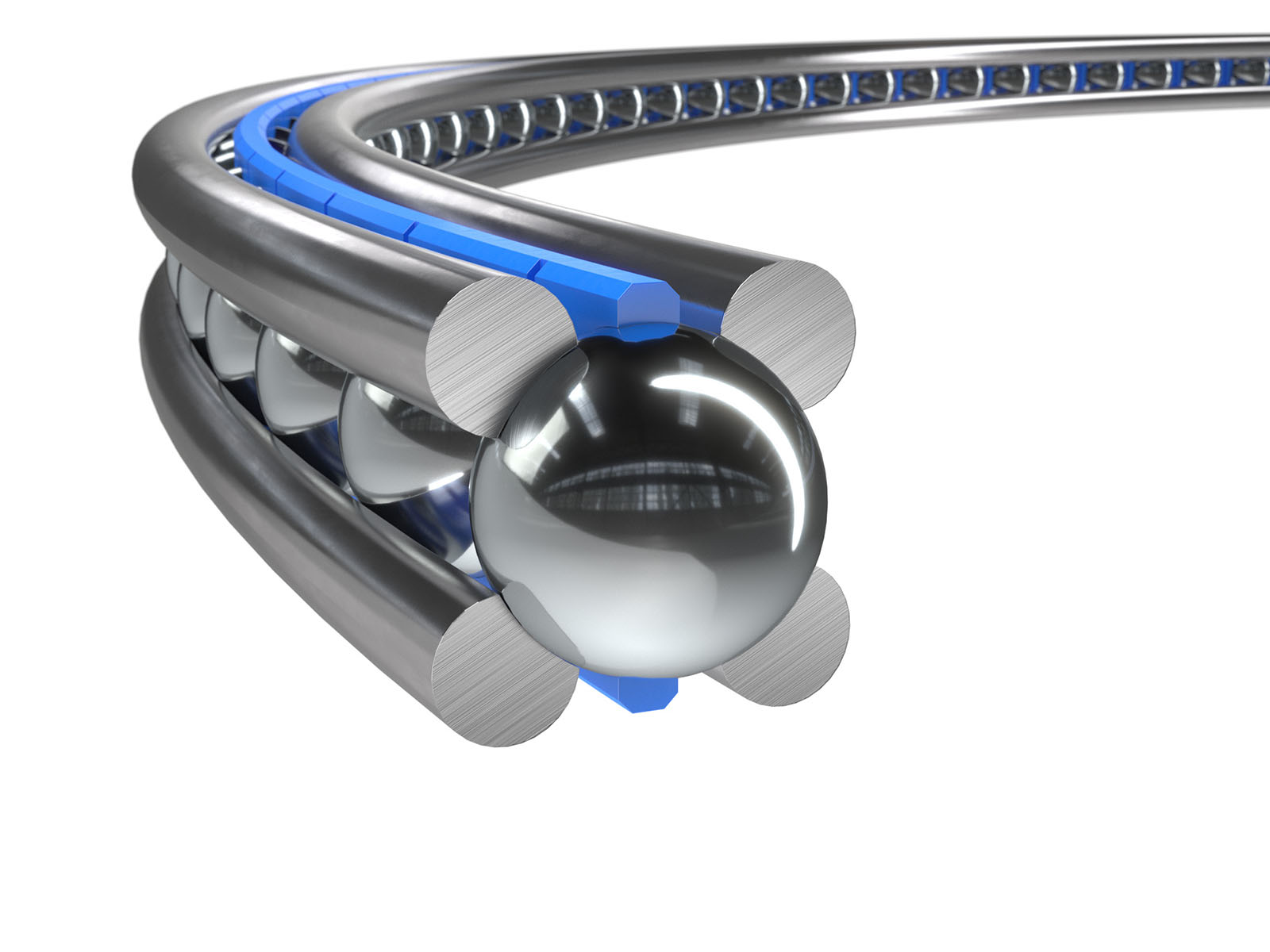

The system is composed of four race rings with ground raceways and a ball cage with retained balls, and is available in two types (LEL and LER) which differ in the cross-sectional geometry.

Since early 2019 the bearing elements product has also been offered in type LEW with crosswise arranged rollers offering high levels of rigidity and excellent sliding even in the presence of significant tilting loads.

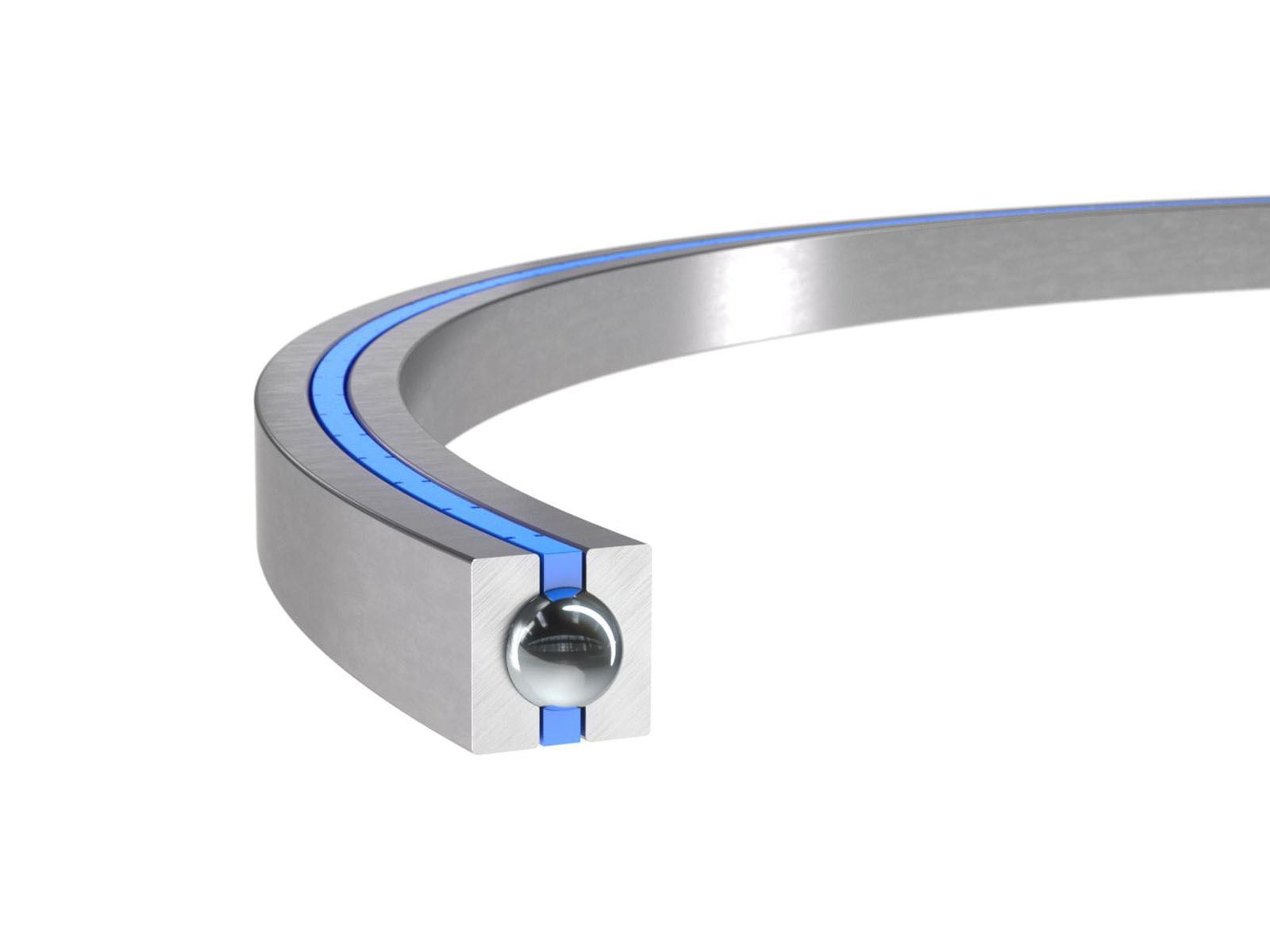

The Franke slim bearing is the most recent member of the range. The product’s extremely compact dimensions make it irreplaceable in many applications.

The slim bearing type is composed of two steel race rings and a ball cage. The most recent version (LSA) is offered in three cross-sections down to 4mm.

A low-cost, easy to use solution which is interchangeable with traditional slim cross-section bearings.

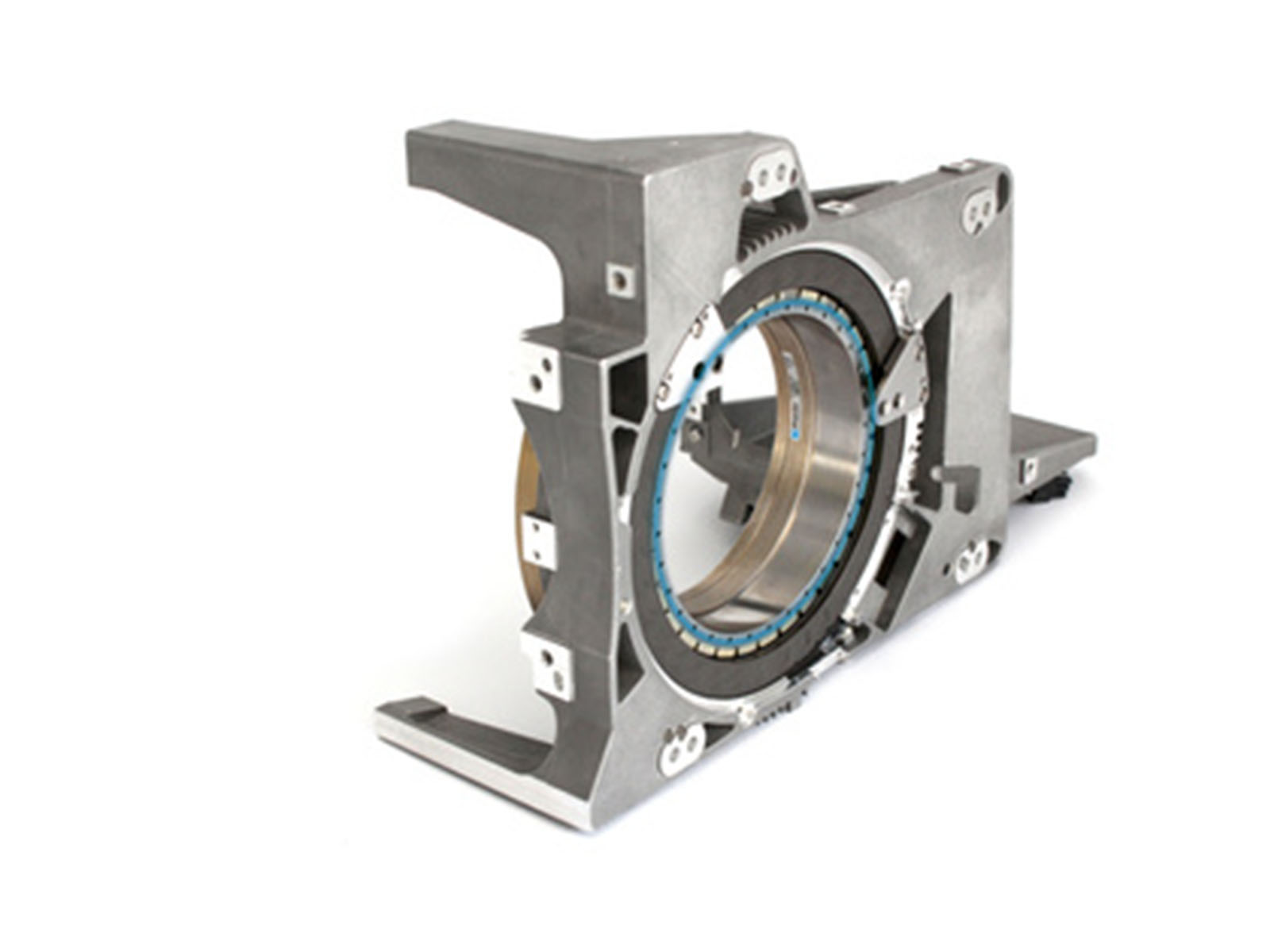

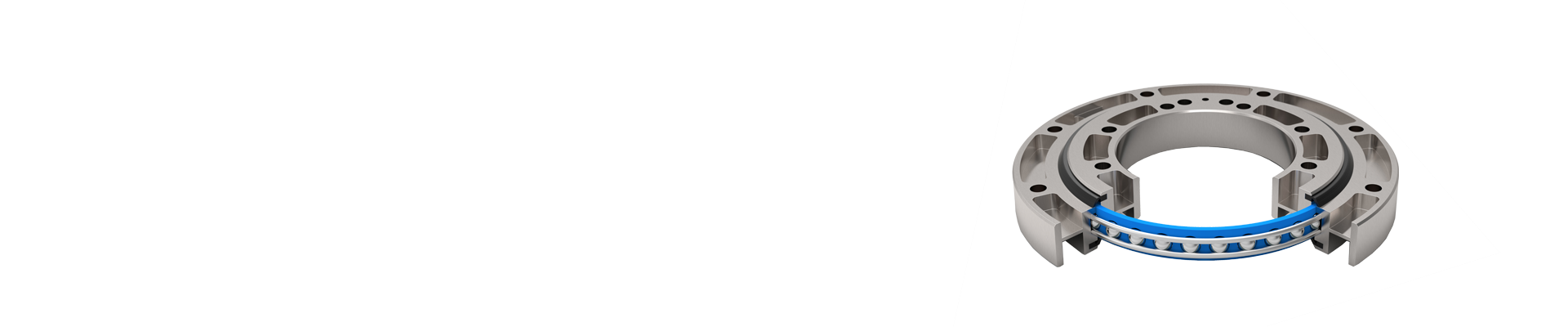

Franke’s bearing assembly is the ready-to-use solution, complete with flange with fastening hole; it differs from traditional slewing rings in terms of weight, dimensions, precision and speed.

Franke uses the same technology described in the bearing elements section to produce these bearing assemblies.

You will therefore find the same characteristics as the bearing elements incorporated in a structure offered in steel (LVA), aluminium (LVB), for high speeds (LVC), in steel with teeth (LVD) and in aluminium with teeth for belts (LVE). Many diameters are also available from warehouse stock.

The most exciting new product this year is the standard range of bearings assembled with integrated Direct Drive torque motor; this new product, known as the Franke LTD bearing with torque motor, is available in four sizes from 100 to 385mm diameter, in steel or aluminium.

LTD is a product which incorporates all components required to automate a rotary movement in a simple manner: a bearing able to support high loads, an integrated brushless motor and measurement system. All in a single unit, without having to couple to motors and drive systems which increase friction and reduce performance. All-in-one. Precise, quiet, clean, simple to use, lightweight and with a large free centre space.