Franke Linear Guides

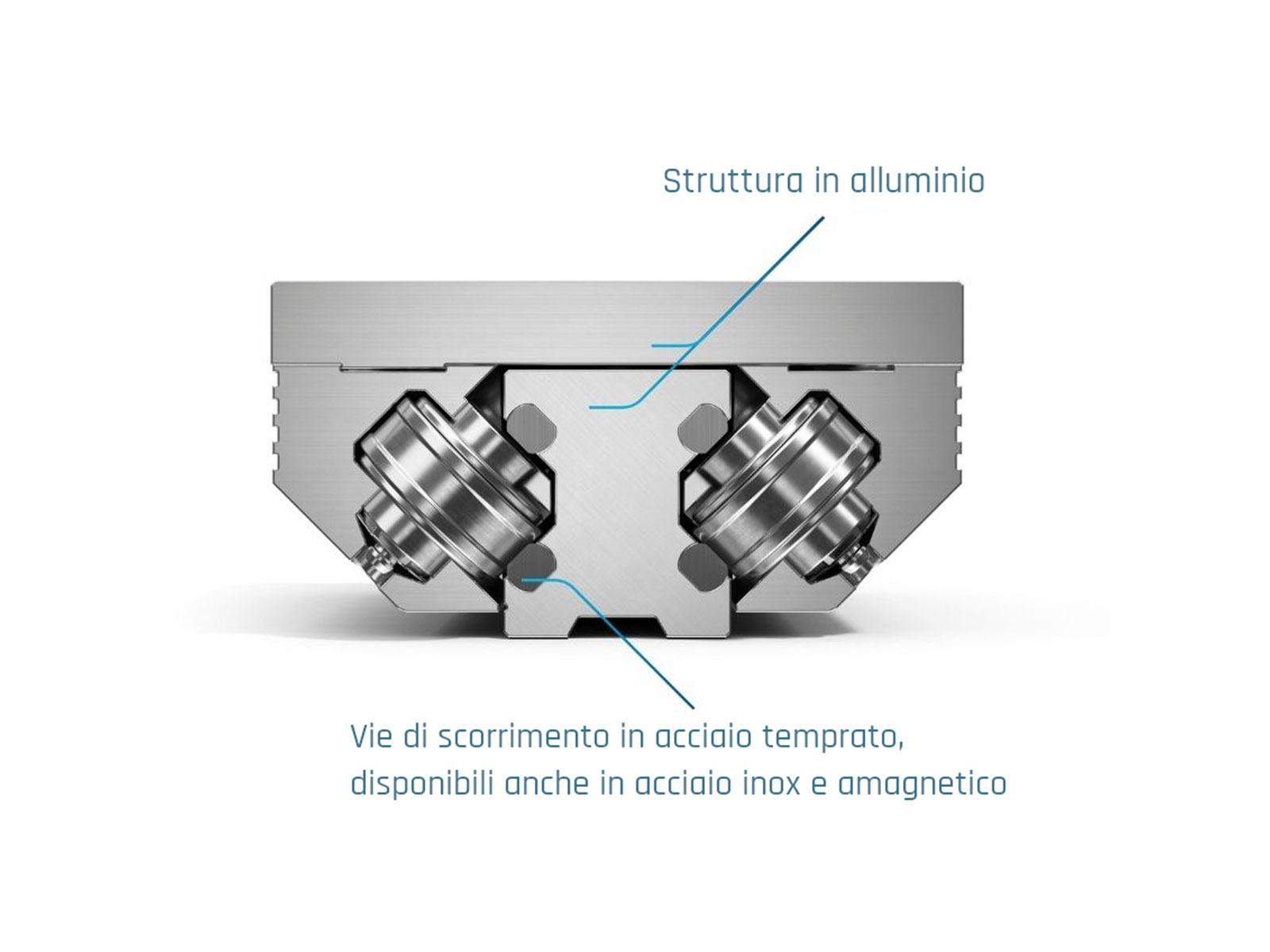

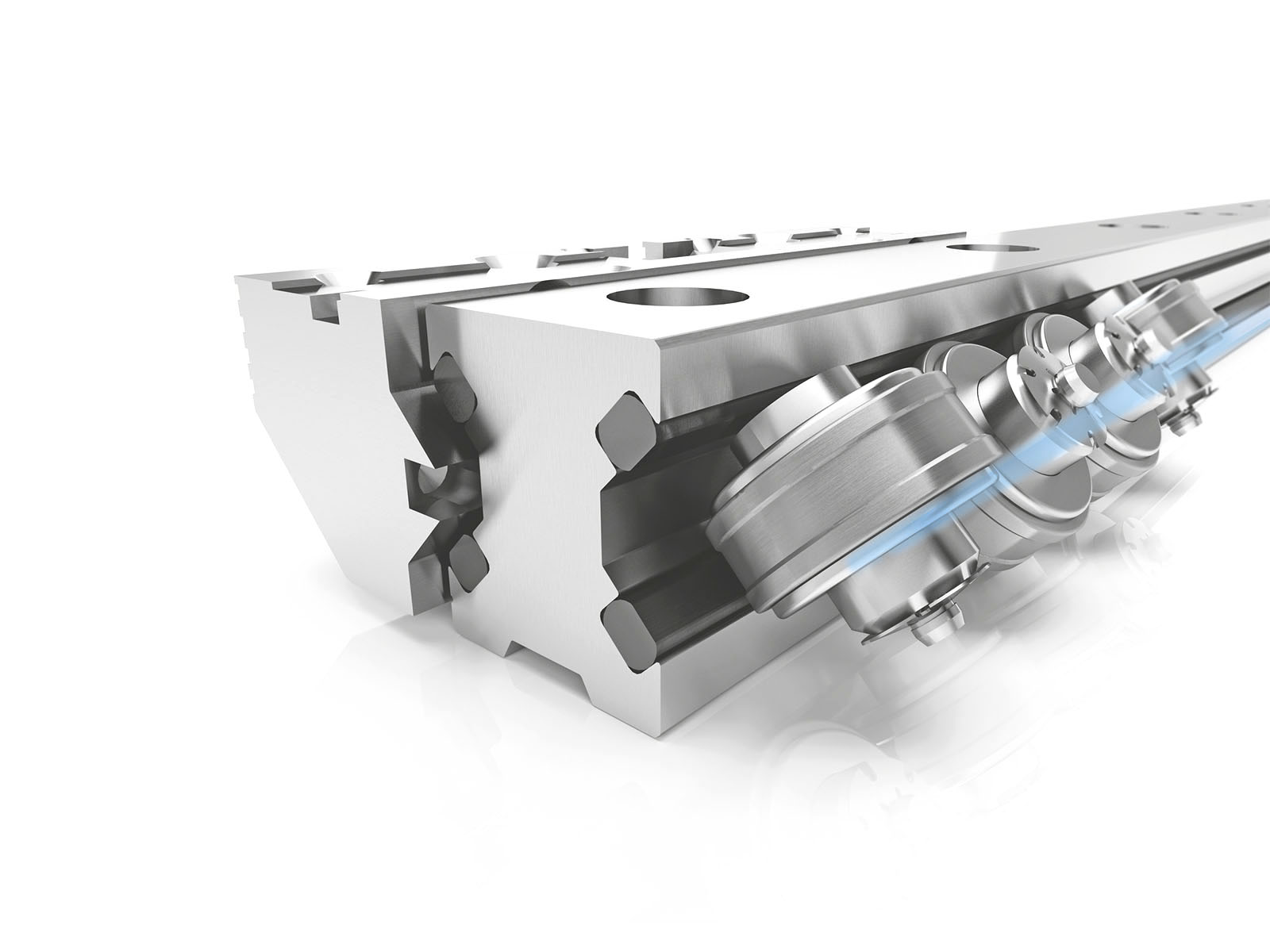

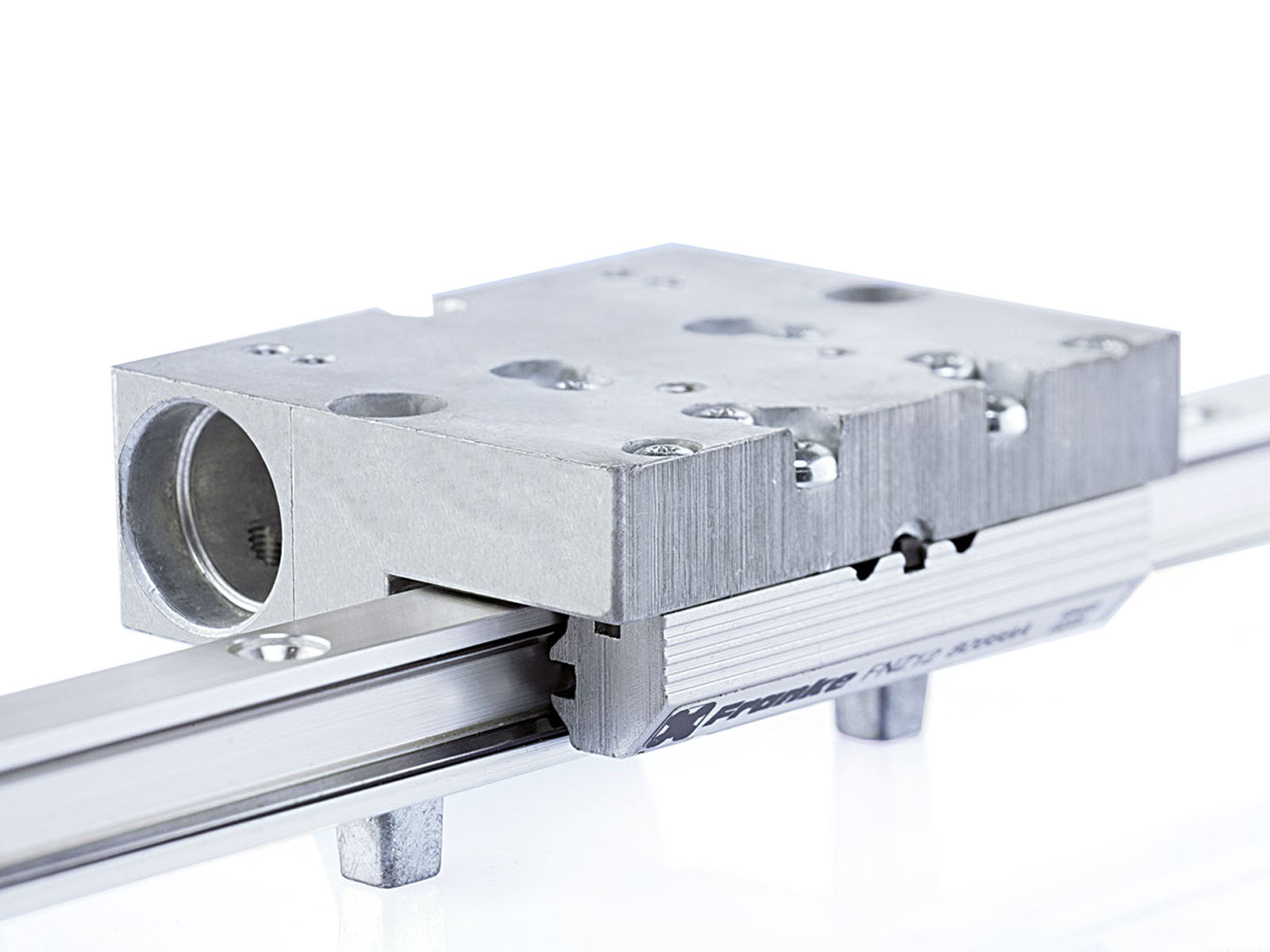

Franke linear guide systems stand out from traditional systems on the market due to many aspects. First and foremost is the materials used: aluminium is used extensively for the rail and cassette structure, offering extremely light weight and excellent corrosion resistance, before we come to the heart of the system, the roller bearings integrated in the aluminium structure of the cassette which slide on steel tracks, pressed into the rail body.

The characteristics outlined above offer numerous advantages of using Franke guides compared to traditional systems, such as:

- Weight reduced by up to 60% compared to equivalent size steel component

- Maximum transfer speed of 10m/sec

- No maintenance required

- Reduction in power required due to low friction

- Faster changes of direction

- Greater durability in the presence of harsh dust and powder

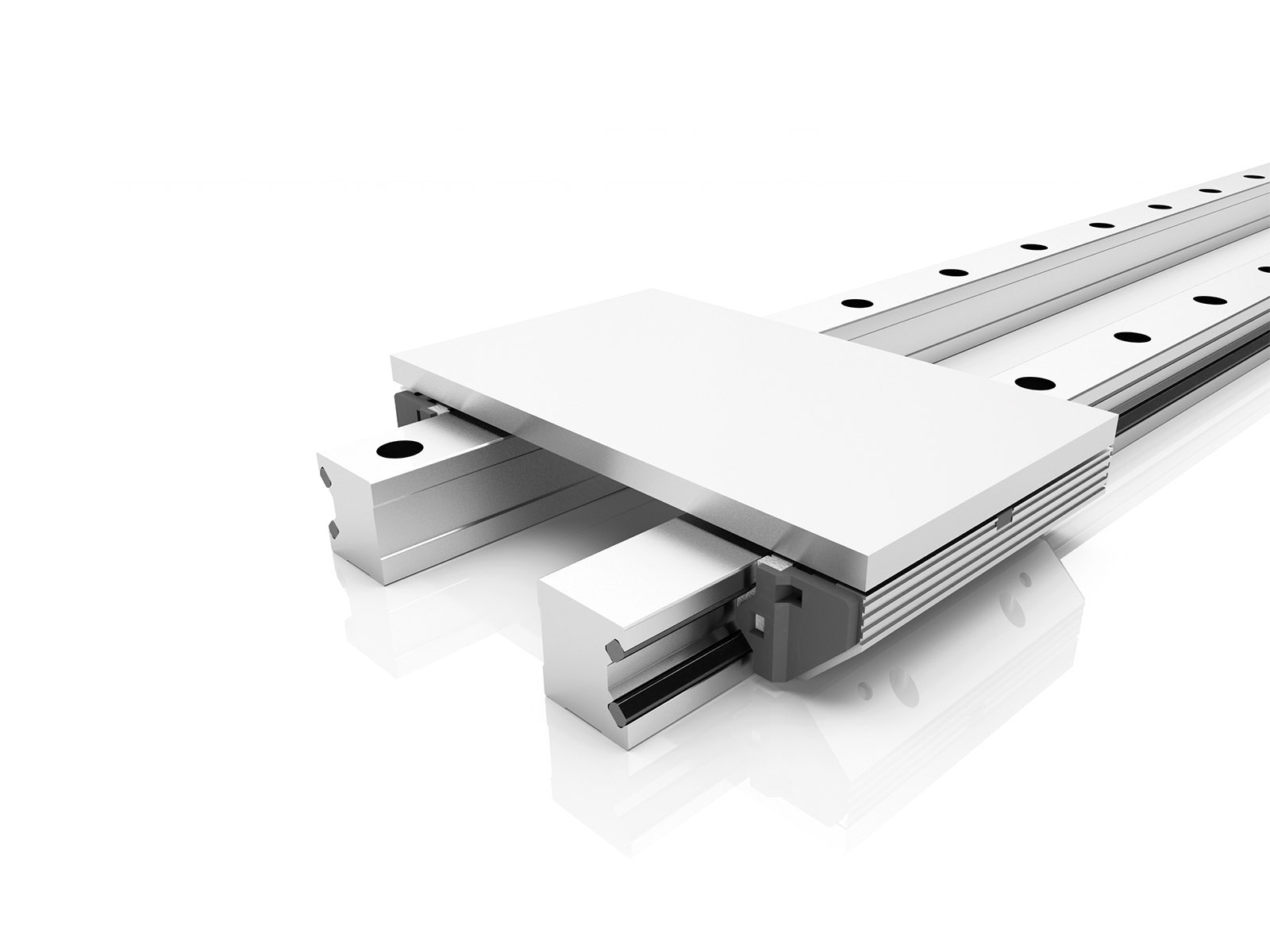

The FTB linear tables stand out for their compact, robust design. The integrated aluminium roller guide is maintenance free and protected from dirt by a metal cover.

The drive system uses a ball screw. Franke FTB type linear tables are suitable for precise processes in many measuring, test and positioning applications. They are available with strokes from 100 to 1500 mm.

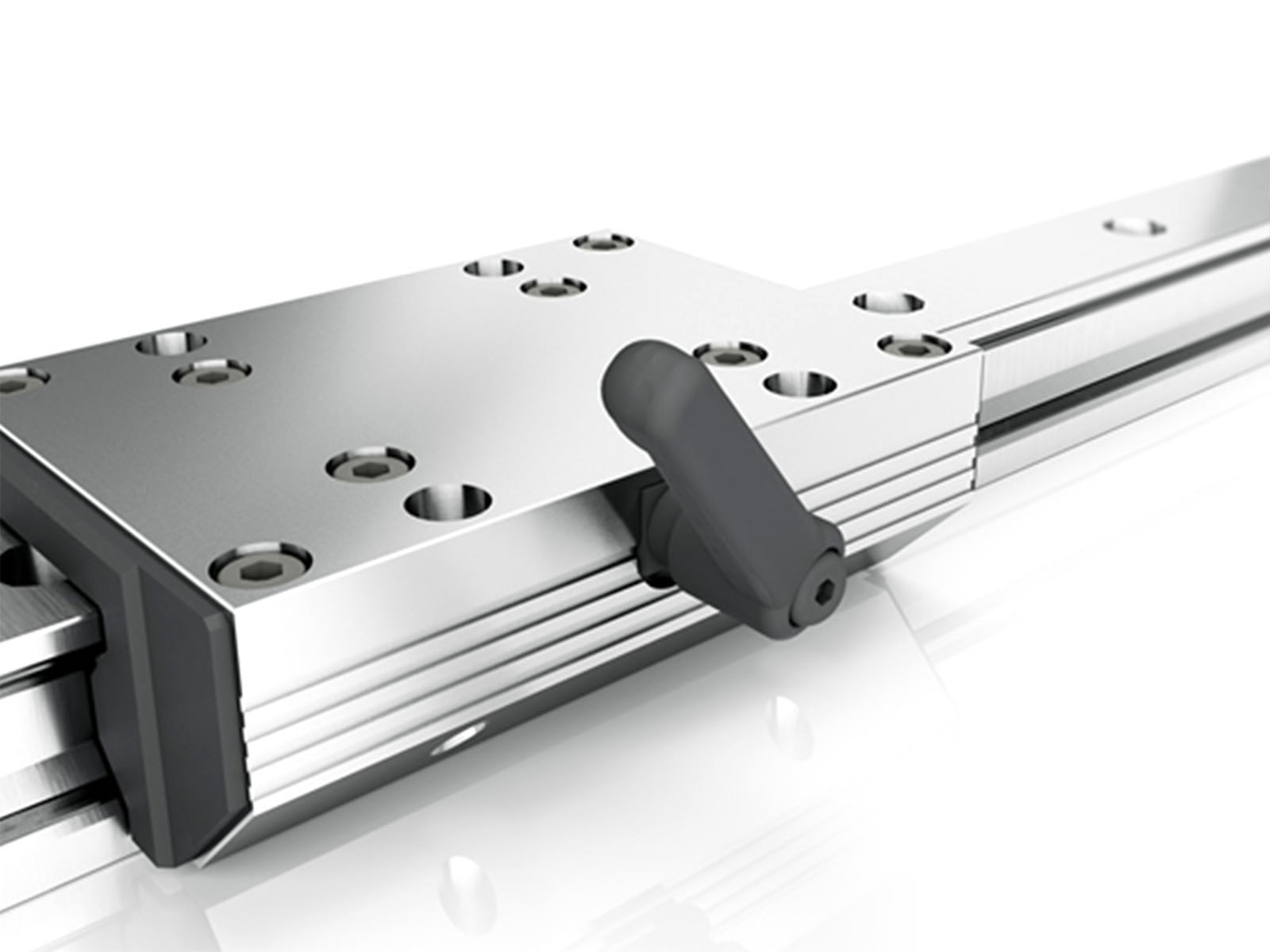

The Franke FTC and FTD linear modules are lightweight positioning units which are supplied ready to install. They are extremely compact and combine the drive system with a timing belt transmission. They are highly versatile and can be used in numerous sectors.

Various versions are available to meet all requirements.

FDA Standard linear guide with aluminium body and sliding parts in tempered steel. Aluminium roller shoe with steel roller bearings.

FDB Lightweight linear guide with aluminium body and sliding parts in tempered steel. Aluminium roller shoe with steel ball bearings.

FDC Corrosion-resistant stainless-steel linear guide with aluminium body and sliding parts in stainless steel. Aluminium roller shoe with stainless-steel roller bearings.

FDD Non-magnetic linear guide with aluminium body and sliding parts in non-magnetic steel. Aluminium roller shoe with non-magnetic steel roller bearings.

FDE Standard linear guide with aluminium body and sliding parts in tempered steel. Aluminium roller shoe with steel roller bearings. Lubricant free.

FDG Non-corrosive, low-cost linear guide with aluminium body and sliding parts in stainless steel. Aluminium roller shoe with stainless-steel ball bearings.

FDI Stainless-steel linear guide with aluminium body and sliding parts in stainless steel. Aluminium roller shoe with stainless-steel roller bearings suitable for high-vacuum applications.