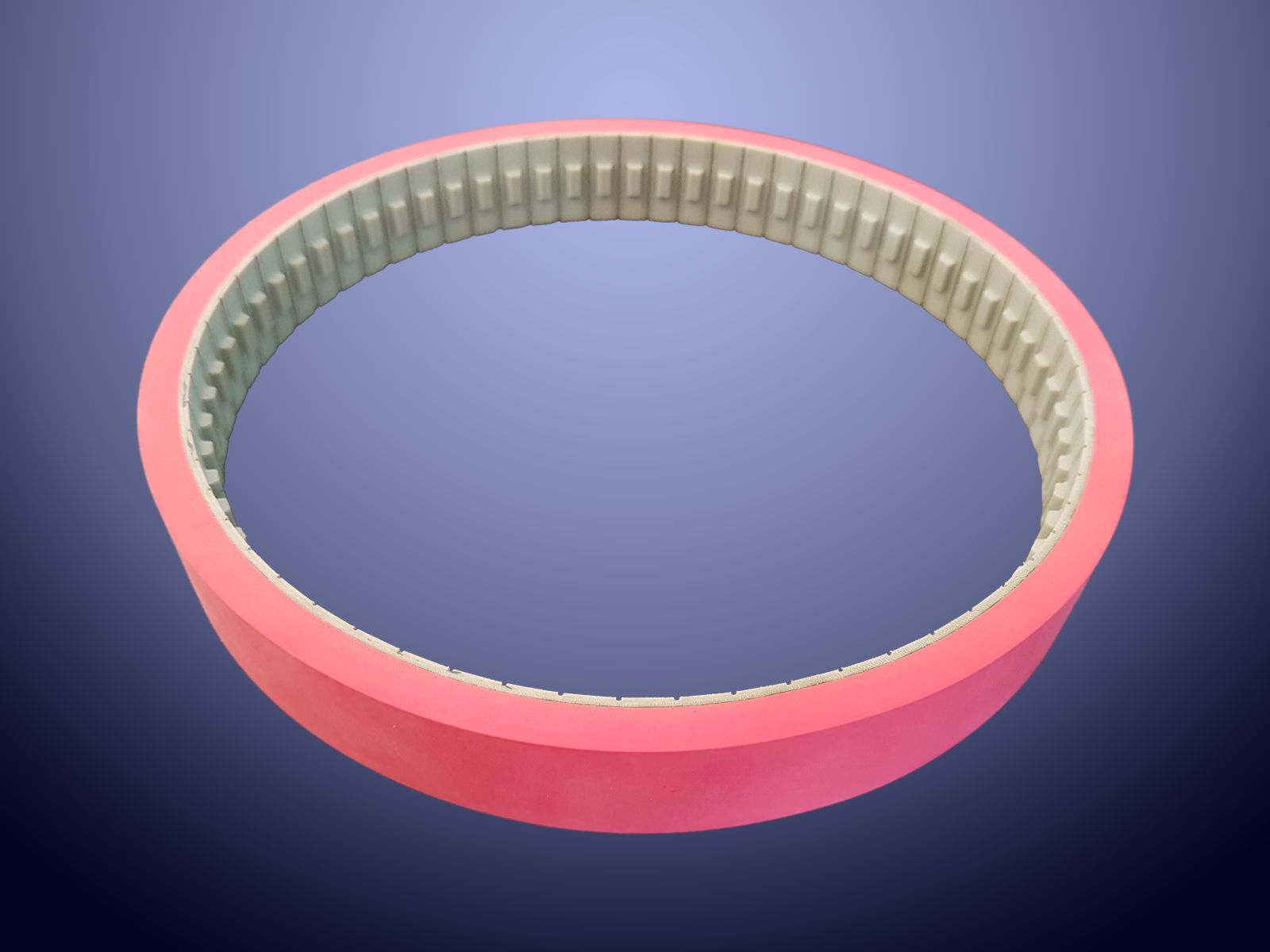

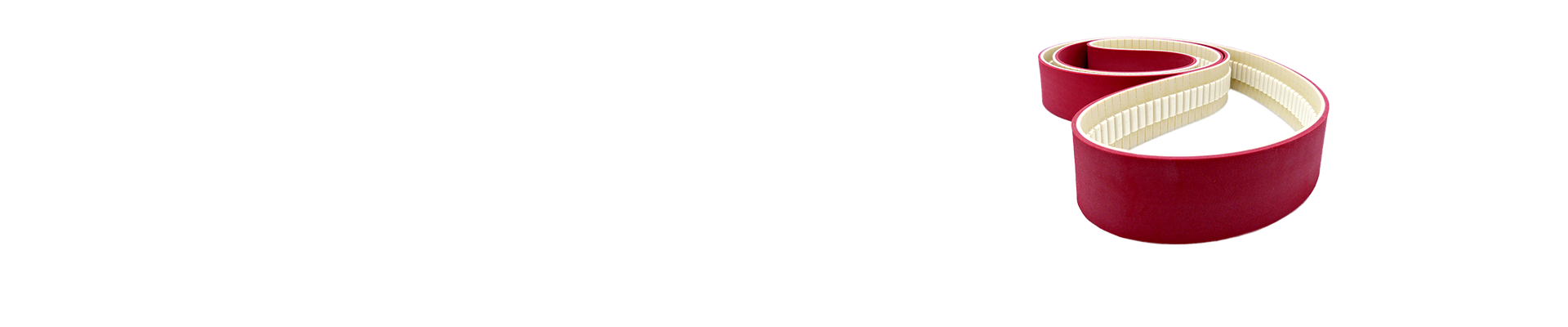

Timing Belts

with Cover

There is a huge range of coatings which can be applied to the back of timing belts, and depending on the specific application requirements we can recommend the best solution for you in both technical and economic terms.

The cold-glued coatings category is the one which offers the largest number of solutions, thus allowing the specific needs of the conveyor system to best be met.

Our experience allows us to guarantee reliable attachment of any type of coating, regardless of the type of grip or various hardnesses of the coating. (Linatex, Linatrile, food-grade rubber, oil-resistant rubber, etc.).

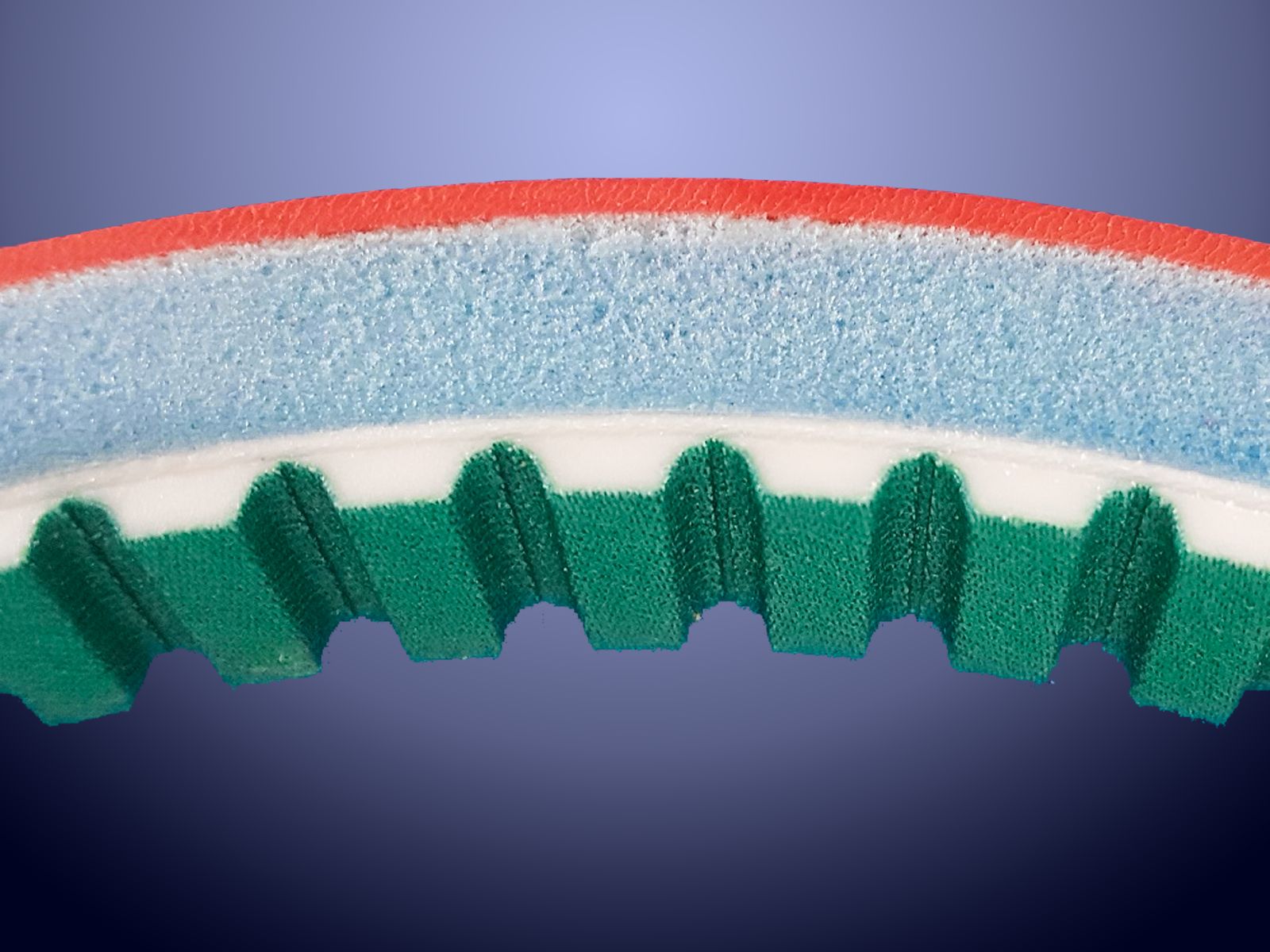

This type of coating is performed through vulcanisation of synthetic rubber on the back of the belt in an autoclave, either natural rubber or polyurethane; the available rubbers have hardness ranging from 45 shore to 80 shore, and can be different colours. (Tenax, para rubber …).

The advantage of this type of coating compared to the cold-applied ones is the excellent adhesion offered by the high temperature, and the excellent price-quality ratio.

Silicone rubber coatings, available in different hardnesses (from 30 to 65 shore), are used primarily for carrying films, pipes and cables, and are moulded on sleeve belts of length less than 1000 mm.

The silicone coating with hardness of around 30 shore is obtained via a hot pour, on the other hand, before subsequent grinding; it is FDA certified and can also be applied to long belts.

Its deformability makes it a good alternative to foams, with the advantage of having a higher level of grip and, as the surface is closed-cell, it can also be used in the presence of liquids.

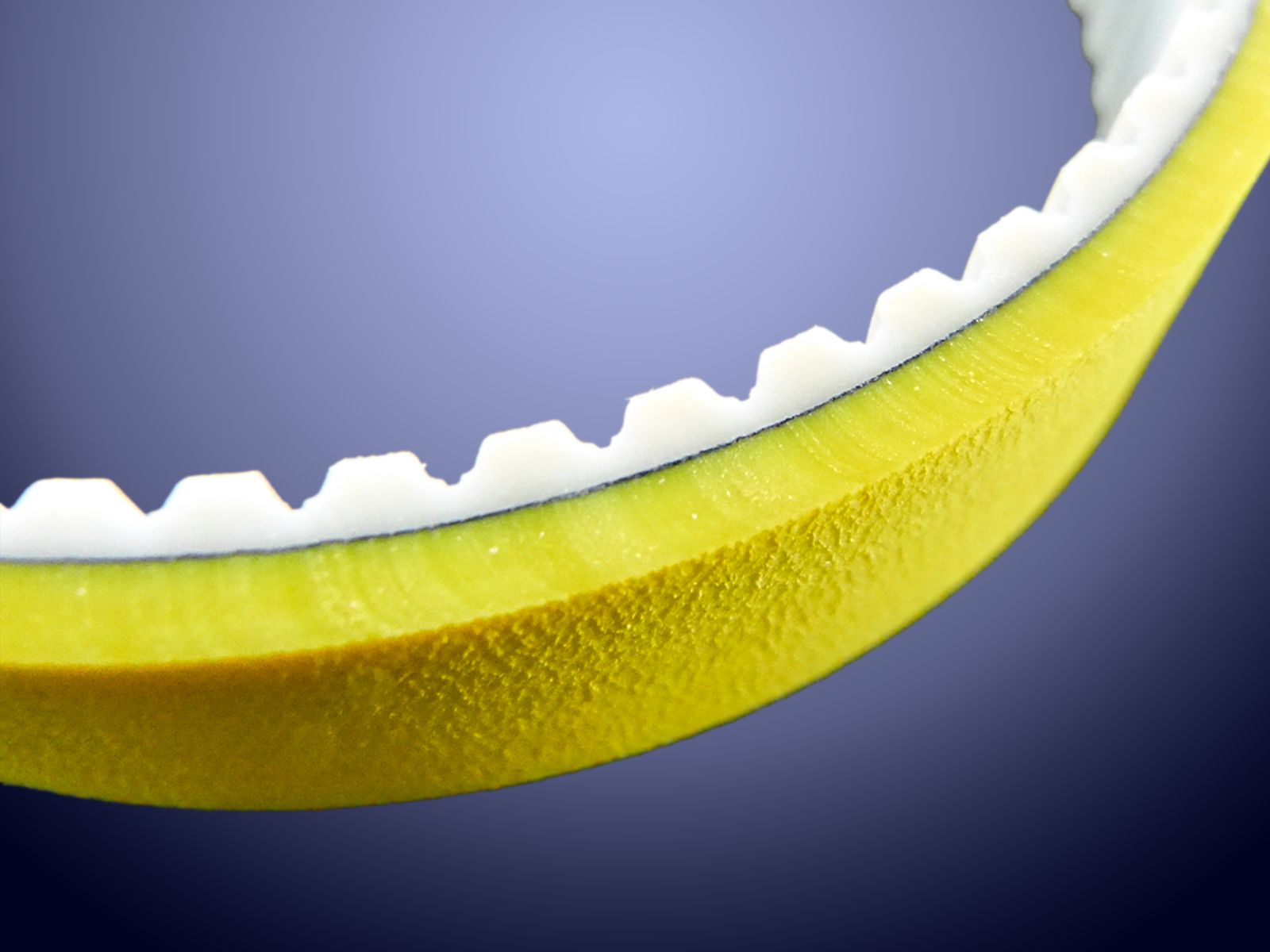

On the back of timing belts supplied by the metre (hardness 92 shore) it is possible to extrude an extra thickness, which can be a softer polyurethane (70/85 shore) or alternatively a mixture composed of rubber and polyurethane (50/60 shore) to increase the grip.

This solution, as well as guaranteeing excellent adhesion between the belt and coating, allows for faster delivery times than other production processes.

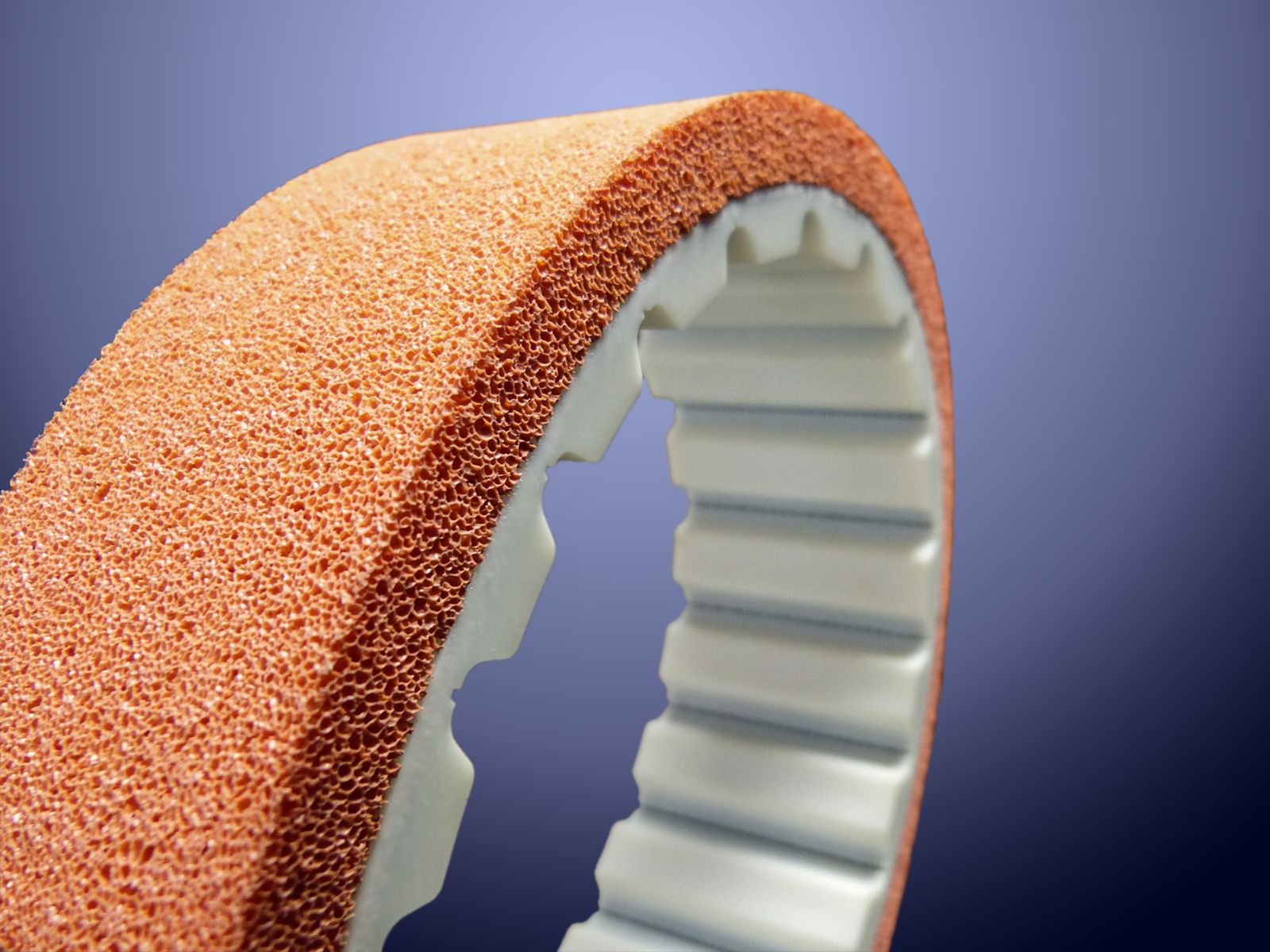

We offer a huge range of foam coatings to transport objects with unusual shapes or fragile products (Sylomer, neoprene foam, foam rubber, …).

Unlike denser coatings, foams are not able to provide a high level of grip and it is therefore possible to apply a dual coating (foam + dense) in these cases in order to obtain the deformability of foam combined with the strength and grip of more solid materials (Silicone, Linatex etc.).